Hydraulic Mud-gun

PEIE Design, Engineering, Manufacture, Supply, Erection &  commissioning 2nd generation Mud-gun machine in TPM methodology with following customer delighting features. We control cost by work hard.

commissioning 2nd generation Mud-gun machine in TPM methodology with following customer delighting features. We control cost by work hard.

|

EXECUTIVE SUMMARY |

||

|

OBJECTIVES |

The intention of this supply is to achieve the minimum criteria for closing the tap-hole of Blast furnace after Hot metal/slag drain or draining condition. |

|

|

FEED MATERIAL |

Ramming Clay/Mug-gun mass, water or Tar bonded |

|

|

EQUIPMENT CAPACITY(Mud Holding Volume) |

60 LITER |

40 LITER |

|

FLOOR REQUIREMENT |

PEIE MUDGUN system 36 m2 without Hydraulic line length |

See detail Matrix |

|

WATER REQUIREMENT |

For cooling of oil at hydraulic oil into heat exchanger , In circuit 10 m3 /hr; Top‐up ~02 m3/hr |

Quality: Treated |

|

POWER REQUIREMENT |

30 KW max |

See detail list |

|

MAJOR EQUIPMENTS |

Mud-gun machine with accessories |

|

|

DELIVERY SCHEDULE |

14 weeks from date of Drawing approval |

|

|

SCOPE OF WORK |

|

|

GENERAL PROCESS DESCRIPTION

|

PROCESS |

|

|

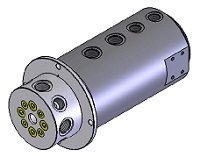

PEIE Mud-Gun consists of a Pedestal with a vertical column holding the swiveling Boom. |

Boom holds the Barrel Unit comprising of Nozzle, [Heat shielded] Barrel, Stroke Indicator, Hydraulic- Cylinders, |

|

Levers and other accessories. During closing, the Mud Gun is brought to tap hole, aligned and clamped by another Hydraulic Cylinder.. |

Then the mud pushed by actuating the pushing Cylinder. |

|

The Mud Gun assembled with Swivel Joint & Hose-less piping system. |

Power pack facilitates to operate the hydraulic actuators |

OPERATIONAL PARAMETERS

|

|

60 Liter |

40 Liter |

|

Swiveling Angle |

180 deg. (Normal)/270 deg. (Max.) |

Yes |

|

Swiveling Time |

5 – 10 sec [adjustable] |

Yes |

|

Plugging angle |

Adjustment lateral +/-20 , Horizontal & vertical +/- 250 |

Adjustment lateral +/-20 , Horizontal & vertical +/- 250 |

|

Adjustment |

lateral +/-20 , Horizontal & vertical +/- 250 |

lateral +/-20 , Horizontal & vertical +/- 250 |

|

Clay Pressure at Nozzle |

55 kg/cm2 |

40 kg/cm2 |

|

Mud Volume |

60 litre |

40 litre |

|

Type of Clay |

Water / Tar Bonded |

Water / Tar Bonded |

|

Holding Force |

5500 kg |

|

|

Injection Speed |

115 mm/sec [adjustable] |

|

|

Nozzle Tip Dia |

100 mm. |

|

|

Conical Nozzle Tip Diameter |

120 mm |

|

|

Barrel Size |

300 mm dia. x 850 mm |

|

TECHNICAL DETAILS / SPECIFICATION (HYDRAULIC COMPONENTS )

|

Hydraulic Power Pack |

|

|

a) Tank Material & Capacity b) Description of various Fittings c) Overall Dimension d) Oil Specification and Quantity e) Weight including Oil f) Cooling Water reqd, Qty & Pipe Size g) Make of Power Pack |

a) IS 2062 & 180 Gallon b) SW Fitting c) After detail engineering. d) Servo system HLP-68, 800 Lt. e) Later f) Details later g) Rexroth / Parkar |

|

Pump for Cylinder Operation |

|

|

a) Discharge b) Pressure: c) Flow: d) Make e) Motor Make & Rating (KW): |

a) Dual Delivery Vane [1 W + 1 S] b) 160 kg/cm2 c) 140 lpm d) Parker / Rexroth e) Siemens / ABB & 55 KW [Class F/B] |

|

Hydraulic Motor (Swivelling) |

|

|

a) Geometric Displacement: b) Geometric Torque: c) Inlet differential Pressure: d) Max. Speed: e) Operating Speed: f) Make: |

a) 42 cc/rev b) 7.02 NM/bar c) 293 bar d) 450 rpm e) 100 rpm f) Danfoss / Parker |

|

Hydraulic Cylinder [Mud Pushing] |

|

|

a) Bore Diameter b) Rod Diameter. c) Stroke : d) Type: e) Barrel Mounting. f) Piston Rod Mounting: g) Rod & rear end Port location h) Make: |

a) 200 mm b) 125 mm c) 850 mm d) Front Flange e) Front Flange f) Std. g) Horizontal upward h) ESS Hyd / Hydrocraft. |

|

Hydraulic Cylinder [Clamping] |

|

|

a) Bore Dia.: b) Rod Dia.: c) Stroke : d) Type: e) Barrel Mounting: f) Piston Rod Mounting : g) Rod & rear end Port location: h) Make: |

a) 125 mm b) 90 mm c) 400 mm d) Front Flange e) Std. f) Std. g) vertical upward i) ESS Hyd / eqvl. |

|

Flexible Hose Pipes: |

Hose-less piping system |

|

Material of construction |

|

|

a) Base Frame & Linkage: b) Body: c) Mud Barrel : d) Mud Barrel Tip : e) Weld Inspection: |

a) IS 2062 & MS/C45 b) IS 2062 c) Seamless Pipe d) Steel casing / s.s. e) DP [wherever necessary] |

|

ELECTRICALS |

|

|

a) Starter Panel

b) Control Console

c) Limit Switches |

|

|

PAINTING |

Heat Resistant Paint |

|

OPERATING STATION |

Control push button Operators’ Stations located at safe and visible place to the tap hole |

The Boom swivels through a gear train operated by a Hydraulic Motor.

The Boom swivels through a gear train operated by a Hydraulic Motor.

commissioning 2nd generation Tap hole Drill machine in TPM methodology with following customer delighting features. We control cost by work hard.

commissioning 2nd generation Tap hole Drill machine in TPM methodology with following customer delighting features. We control cost by work hard.