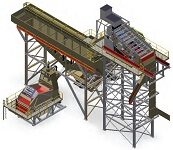

Technical data and process for Iron ore washing, screening & beneficiations plant

PEIE Design, Engineering, Manufacture, Supply, Erection & commissioning 3rd generation Ore Washing, Screening & Beneficiations Plant in TPM methodology with following customer delighting features.

PEIE Design, Engineering, Manufacture, Supply, Erection & commissioning 3rd generation Ore Washing, Screening & Beneficiations Plant in TPM methodology with following customer delighting features.

We control cost by work hard

| EXECUTIVE SUMMARY |

|

OBJECTIVES |

The Purpose of this project is to achieve the minimum criteria for continuous production of Washed Iron ore For and Of Different specific sizes. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

a) Blast Furnace b) D.R.I or Sponge Iron c) Sinter plants d) Pelletization |

i) (-40+18) mm ii) (-18+10) mm iii) (-10+6) mm iv) (- 6+3) mm v) (- 3+0.05) mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

FEED MATERIAL |

Material: Iron Ore |

Feed Size: <40mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

PLANT CAPACITY |

80 Ton/Hour (Max 100 tph) |

40 Ton/Hour (Max 50 tph) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

LAND REQUIREMENT |

PEIE Ore Washer system 380 m2 without stockpile (detail Matrix below) |

PEIE Ore Washer system 180 m2 without stockpile (see detail Matrix) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

WATER REQUIREMENT |

In circuit 250 m3 /hr; Top‐up ~25 m3/hr, hold up: 200m3 , (Quality: treated) |

In circuit 100-120 m3 /hr; Top‐up ~30 m3/hr, hold up: 200m3 , Quality: Non-specified |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

POWER REQUIREMENT |

245KW max (detail list below) |

160 KW max (detail list below) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

MAJOR EQUIPMENTS

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

DELIVERY SCHEDULE |

12 weeks from date of Drawing approval |

12 weeks from date of Drawing approval |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

SCOPE OF WORK |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

BENEFICIATION THEORY

|

Using of Iron Ore |

Grades and particle sizes. |

|

|

a) Blast-Furnace b) D.R.I or Sponge Iron c) Sinter plants d) Pelletization |

a) normally (-40+10) mm. somewhere (-40+6)mm b) normally (-18+6)mm somewhere (-18+3)mm c) normally (-10+3) somewhere (-6+3)mm d) normally < 0.5 mm. somewhere (-3+0.5)mm |

|

|

OBJECTIVE |

A) Desired : To achieve a high FE grade value (>62%) and low values for unwanted contaminants for cost effective processing. B) Not desired : Low FE value of the ore (< 62%) burn off with unwanted contaminants into F/C or Kiln ~ cost ineffective production Ore Oxide (Fe2O3) ~ increasing production costs. |

|

|

PEIE-100 Iron washing plant introduction example |

Increase in Iron from 58.24% to 63.2% ↑which delivers significant efficiency savings in downstream processes. ↓results 37% reduction in Alumina from 4.3% to 2.7% and a 32% reduction in Silica from 6.6% to 4.5%. ↓results Reduction in Coal consumption of around 5% ↓results significant efficiency gain in steel production processes |

|

|

|

| ======> |

| ===> |  |

| ===> |

| ===> |  |

| SCOPE OF SUPPLY AND FABRICATION ERECTION |

|

SCOPE |

|

|

Supply ( PEIE’s Scope) |

above |

|

Manufactured items |

above |

|

Fabricated items |

At site |

|

Electrical Items |

above |

|

Optional Items |

Details later |

|

Noted Exclusions |

1)All Civil foundation, building, control room, settling pond, pump house, water channel. 2)All electrical cable and accessories, 3)Factory illumination, 4)Crane, Winch and any handing equipment, 5)Any item not specified in the scope of supply |

|

INSTALLATION FACILITIES NEEDED |

1)Civil clearance for equipment erection. 2)Site facilities like un-interrupted power, Temporary storage and Fabrication space , Industrial LPG and oxygen gas, Hydra to lift 4 ton etc., have to be arranged by you 3)Permit for our welding work at night |

ed @80 tph of Iron ore to the circuit. The Hopper is fitted with Grizzly of 100 mm2 size to eliminate oversized material to Screen.

ed @80 tph of Iron ore to the circuit. The Hopper is fitted with Grizzly of 100 mm2 size to eliminate oversized material to Screen. from the feed material.

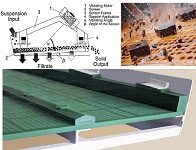

from the feed material. The (-18+10) mm bottom panel overflow product of the screen will be fed to PEIE log washers for further scrubbing. The under‐flow of the screen i.e. (‐)10mm and slurry water is sent to the PEIE-50 OreWasher sump.

The (-18+10) mm bottom panel overflow product of the screen will be fed to PEIE log washers for further scrubbing. The under‐flow of the screen i.e. (‐)10mm and slurry water is sent to the PEIE-50 OreWasher sump. The slurry is pumped to the cyclone and all the ultra‐fines of <50 microns particles taken out of the circuit as overflow of the cyclone. The underflow of the cyclone is dewatered through dewatering screen and gives ‐ 3+0.05mm low moisture final product which stockpiled by using ae stock piled conveyor #4.

The slurry is pumped to the cyclone and all the ultra‐fines of <50 microns particles taken out of the circuit as overflow of the cyclone. The underflow of the cyclone is dewatered through dewatering screen and gives ‐ 3+0.05mm low moisture final product which stockpiled by using ae stock piled conveyor #4. The underflow of Log washer and prograde with any <6mm fines is collected in the sump of the PEIE-50 Ore washer.

The underflow of Log washer and prograde with any <6mm fines is collected in the sump of the PEIE-50 Ore washer.

control the tailings. Dense sludge of circa 800g/litre will be issued from the integrated heavy duty pump for discharge to a designed settlement area.

control the tailings. Dense sludge of circa 800g/litre will be issued from the integrated heavy duty pump for discharge to a designed settlement area. to Settling clear water tank which to be pumped from attached Pump house to water spray for application of this circuit. Thickened and semi solid sludge after semi drying to be removed by pay-loader.

to Settling clear water tank which to be pumped from attached Pump house to water spray for application of this circuit. Thickened and semi solid sludge after semi drying to be removed by pay-loader.